Blown Stretch Film vs. Cast Stretch Film, Which is Better?

Release time: 2025-07-19

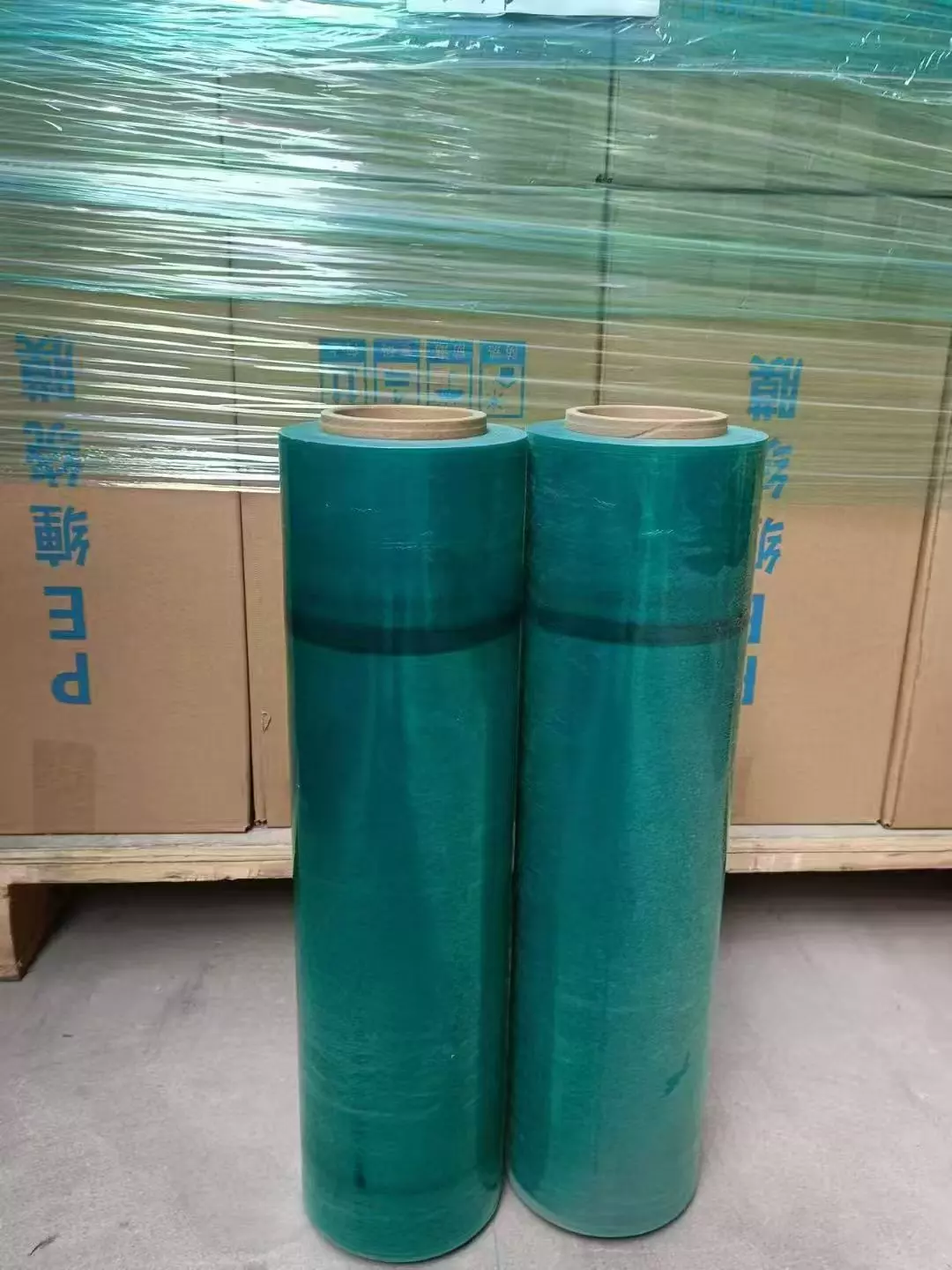

In logistics, transportation, warehousing, and product packaging, stretch films act as silent guardians, tightly wrapping goods. When faced with the two dominant types of stretch films on the market-blown stretch film and cast stretch film-many buyers are left wondering which one best fits their needs. As a professional manufacturer with years of experience in PE stretch film production, Lu’an Xincai Packaging offers an in-depth analysis of the key differences between these two technologies.

Technology Showdown: Root Causes of Performance Differences

Molding Process: Molten plastic is extruded through a circular die to form a tubular film bubble, which is inflated and stretched upward. The film is cooled by air and finally wound into a flat film. Imagine a plastic bubble that is continuously blown upwards and cooled to form.

Core Features: The film bubble cools in the air, which results in a relatively slower cooling process.

Performance:

- Tensile Strength/Puncture Resistance: The molecular chains are more complex, typically resulting in better toughness and puncture resistance. It is especially suitable for packaging goods with sharp edges and corners.

- Transparency/Gloss: Due to the slower cooling process, crystallinity is relatively high, and the transparency and gloss are typically lower than that of cast films.

- Thickness Uniformity: Influenced by air flow and cooling factors, controlling the uniformity of thickness in the transverse direction (TD) is more difficult.

- Adhesion Control: Adhesion is generally more stable and durable, and after pre-stretching, the adhesive performance remains good without peeling.

- Production Efficiency: Line speeds are usually slower than cast film production lines.

Molding Process: Molten plastic is extruded through a flat die slit and directly applied to a large-diameter, high-speed rotating cooling roller where it is rapidly cooled, shaped, and wound.

Core Features: The molten plastic directly contacts a high-precision cooling roller, cooling and forming very quickly.

Performance:

- Transparency/Gloss: The rapid cooling inhibits crystallization, resulting in extremely transparent, glossy film that showcases products perfectly.

- Thickness Uniformity: Due to the precision control of cooling rollers, thickness tolerance in both the machine direction (MD) and transverse direction (TD) is minimal (up to ±3 microns), with excellent flatness.

- Tensile Performance: The MD direction exhibits excellent stretching performance, but the TD direction is weaker. The film is softer when stretched.

- Adhesion Control: Initial adhesion is high, but after pre-stretching, the adhesion tends to decrease more quickly than blown film.

- Production Efficiency: Line speed is extremely high, ensuring great capacity.

Blown Film vs Cast Film

| Characteristics | Blown Stretch Film | Cast Stretch Film |

| Transparency/Gloss | Medium | Extremely High |

| Thickness Uniformity | Good | Excellent |

| Toughness/Puncture Resistance | Excellent | Good |

| Stretch Performance | Balanced | Excellent in MD, Weaker in TD |

| Adhesion Durability | Excellent | Good |

| Production Efficiency | Medium | Extremely High |

Application Scenarios: It’s Not About What’s Best, But What’s Most Suitable

Choose Blown Stretch Film when you need:

- Protection for Sharp-edged Goods: Packaging furniture, metal products, and equipment with corners. Its excellent toughness and puncture resistance are crucial for safe transportation.

- Long-term Stable Wrapping: Goods that will be stored for extended periods or need to be transported multiple times. Its lasting adhesion and good retraction force ensure long-term stability.

- Cost Efficiency: When performance requirements are met, blown films typically offer a cost advantage.

Choose Cast Stretch Film when you need:

- Exceptional Display Effect: Packaging high-end electronics, gifts, retail products, etc. Its crystal-clear transparency and high gloss can perfectly showcase the product’s appearance.

- High-speed Efficient Packaging: When used with high-speed automated packaging lines (such as for beverages, food, and daily chemicals), its extremely high line speed and excellent flatness ensure efficiency.

- Precision Stable Wrapping: In scenarios that require extremely uniform thickness and flatness (such as for precision instruments or pharmaceutical intermediates), cast film is the reliable choice.

- Lightweight Needs: It is easier to produce thinner yet stable films.

Lu’an Xincai: Customized Solutions to Break Through Process Limitations

At Lu’an Xincai, we understand that a one-size-fits-all solution doesn’t meet the ever-changing demands of the market. Whether it’s blown or cast film, we have mature production lines and a strict quality management system (ISO9001 certified) to ensure the reliable quality of every roll of stretch film.

Our Core Advantages:

- Material Selection: We select different grades of PE resin and precisely adjust melt index and density to meet specific adhesion, strength, and weather resistance requirements (e.g., UV resistance, low-temperature resistance).

- Formula Optimization: We independently develop adhesive layer formulas and can customize various features such as ultra-strong adhesion, reduced adhesion, anti-fog, and anti-static.

- Flexible Specifications: Film width, thickness, core size, roll weight, and roll shape can be customized according to customer equipment and usage habits.

- Process Optimization: For specific applications (e.g., heavy-duty wrapping, high-speed production lines, refrigerated environments), we optimize the blown or cast film process parameters to maximize product performance.

Lu’an Xincai Packaging Materials Co., Ltd. is committed to becoming your trusted packaging partner with professional technical expertise and flexible customization capabilities. Whether you prioritize toughness and protection or high transparency and efficiency, we provide the most suitable PE stretch film solutions to ensure the safety and efficiency of your goods. Contact Lu’an Xincai now to get your customized stretch film solution!