Hand Stretch Film Safety Tips for Manual Wrapping

Release time: 2025-12-18

Table of Contents

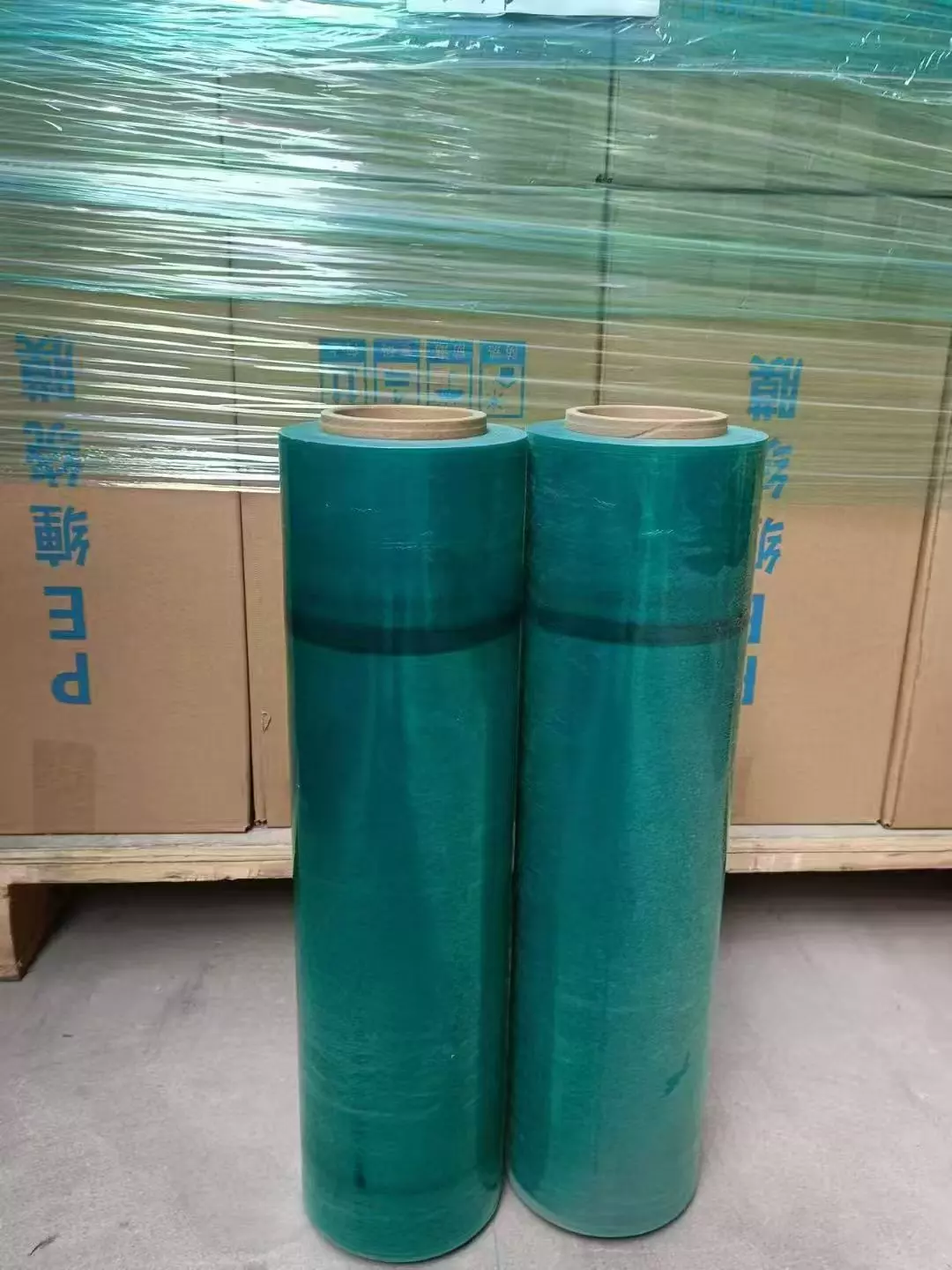

Hand stretch film is widely used in warehouses, logistics centers, and manufacturing facilities for securing palletized goods. While manual wrapping is flexible and cost-effective, improper handling can lead to worker injuries, damaged loads, and reduced productivity. Understanding and applying proper safety practices is essential to ensure efficient and safe operations. Below are key safety tips to follow when using hand stretch film for manual wrapping.

1. Use Proper Wrapping Posture

One of the most common risks during manual wrapping is musculoskeletal strain. Operators often bend, twist, or reach excessively while wrapping pallets. To reduce injury risk, workers should maintain a neutral spine position, bend at the knees instead of the waist, and avoid sudden twisting motions. Walking around the pallet rather than stretching across it helps maintain balance and reduces back strain.

2. Choose the Right Hand Stretch Film

Selecting the correct type of hand stretch film plays a major role in safety. Using film that is too thick or has low stretchability requires excessive force, increasing the risk of muscle fatigue. Pre-stretched hand stretch film is often a safer option, as it requires less effort to apply while still providing strong load containment. Choosing the appropriate film width and thickness also improves handling comfort and control.

3. Use Film Dispensers and Safety Tools

Manual wrapping without a dispenser can strain wrists and hands. Hand-held stretch film dispensers help maintain consistent tension and reduce repetitive stress injuries. These tools also minimize direct contact with film edges, lowering the risk of cuts or abrasions. In high-volume environments, ergonomic dispensers are a simple yet effective investment to improve workplace safety.

4. Maintain Clear and Stable Work Areas

Before wrapping begins, ensure the pallet is placed on a stable, level surface. Uneven floors or unstable loads increase the likelihood of slips, trips, or falling goods. Clear the surrounding area of obstacles and ensure adequate lighting so workers can move safely around the pallet during wrapping. Proper spacing also prevents collisions with other equipment or personnel.

5. Apply Even Tension and Secure the Load Properly

Overstretching the film can cause it to snap unexpectedly, posing a safety hazard. Applying even, controlled tension reduces the risk of film breakage while ensuring proper load stability. Start wrapping at the base of the pallet to anchor the load securely, then work upward with overlapping layers. A well-secured load minimizes the risk of product shifting or falling during transport.

6. Wear Appropriate Personal Protective Equipment

Although manual wrapping may seem low-risk, basic personal protective equipment (PPE) is still important. Anti-slip safety shoes help prevent falls, while gloves can improve grip and protect hands from minor cuts or friction burns. PPE should be appropriate for the work environment and not restrict movement during wrapping tasks.

7. Provide Training and Follow Standard Procedures

Proper training is essential for safe manual wrapping. Workers should be instructed on correct wrapping techniques, equipment usage, and load stability principles. Establishing standardized wrapping procedures ensures consistency and reduces unsafe practices. Regular refresher training helps maintain awareness and encourages safer habits over time.

8. Monitor Fatigue and Workload

Manual wrapping is physically demanding, especially in high-volume operations. Employers should monitor workload and rotate tasks to prevent fatigue-related injuries. Adequate breaks and realistic productivity targets help maintain both safety and efficiency.

High-stretch hand stretch film is a reliable packaging solution when used correctly, but safety should never be overlooked. By choosing the right film, using proper tools, maintaining good posture, and providing adequate training, businesses can significantly reduce injury risks while improving wrapping efficiency. Implementing these safety tips not only protects workers but also ensures secure loads and smoother logistics operations.